Stripping 1000

Easy Off

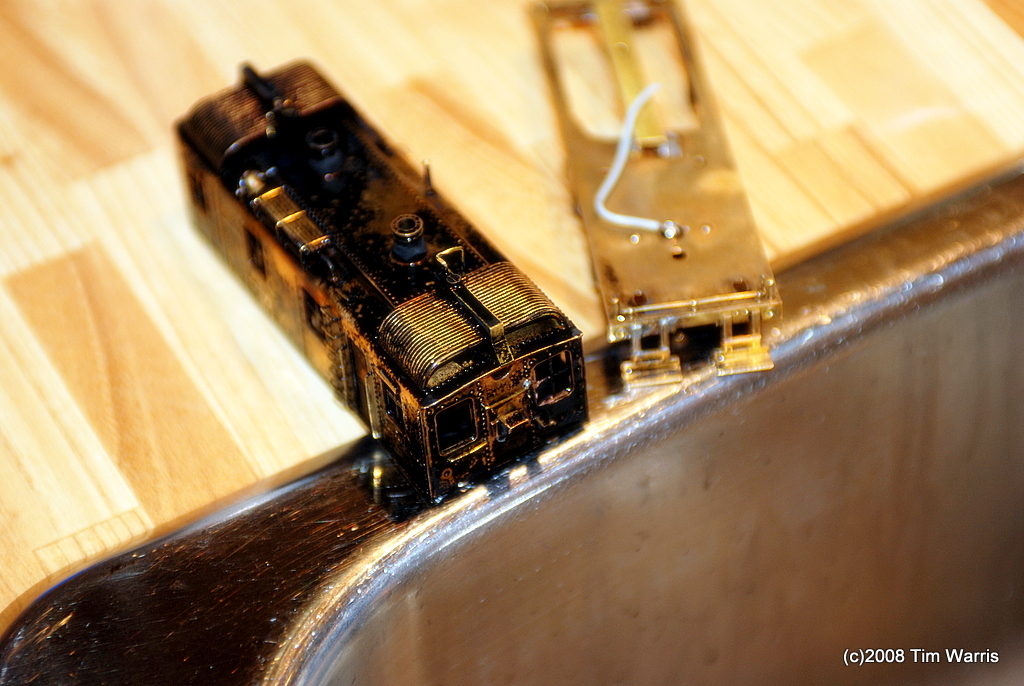

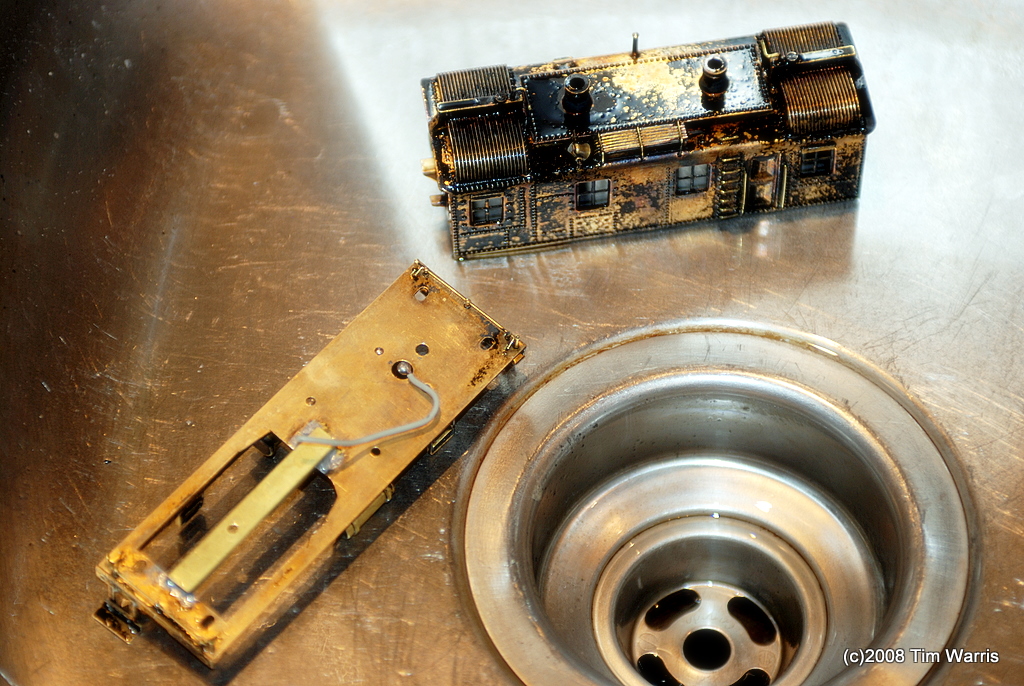

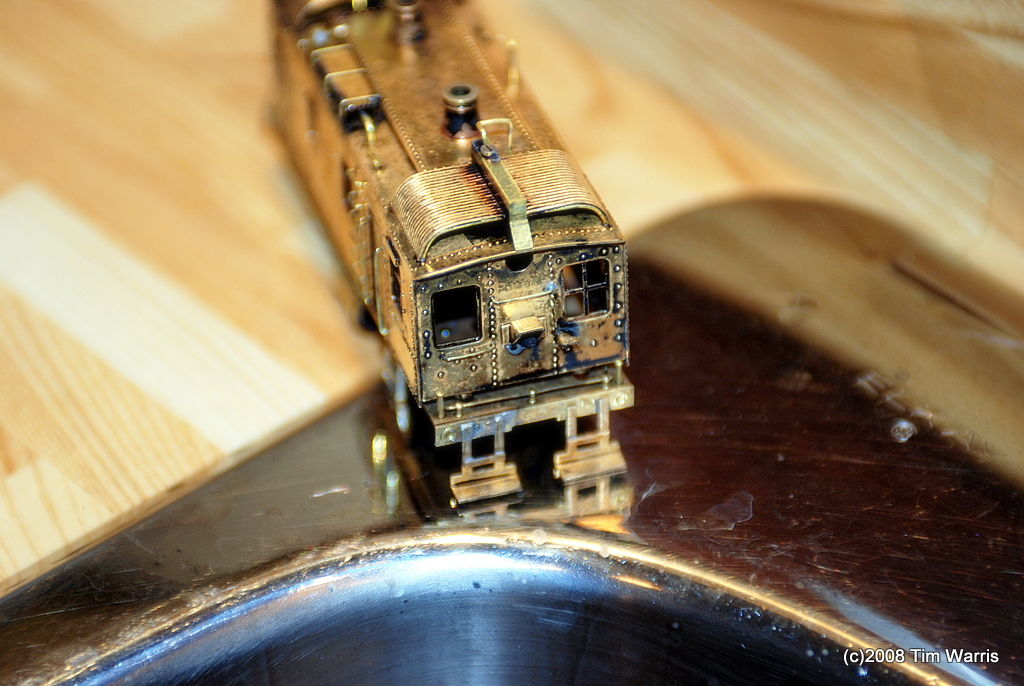

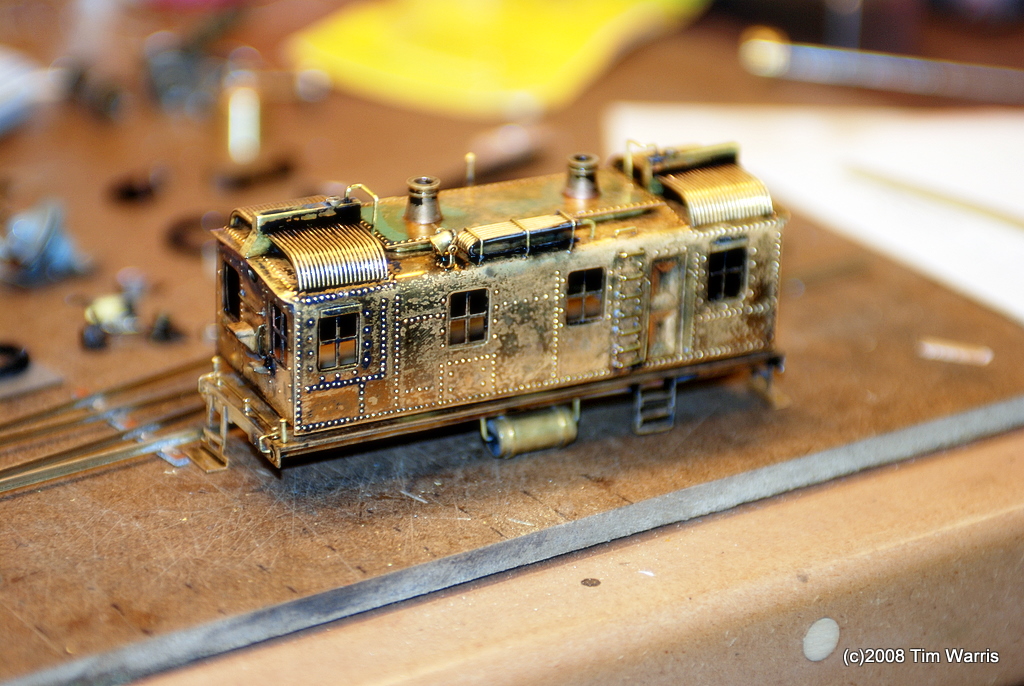

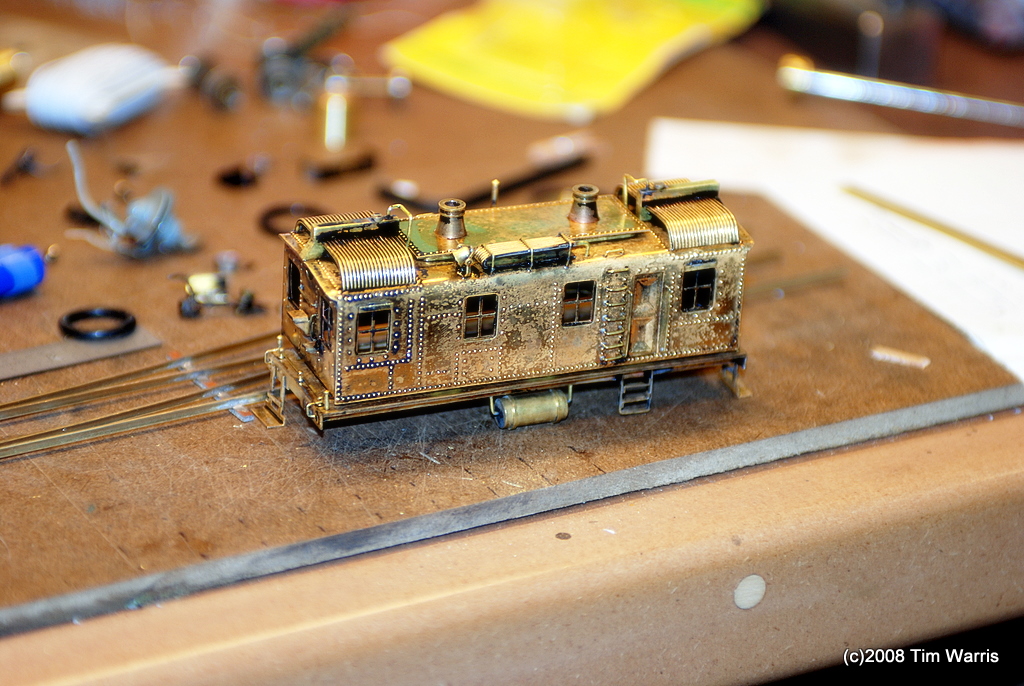

With the remotor project just about complete, I decided to strip the paint from the boxcab. I need to repair a few loose parts and the only way to properly solder them back onto the shell is to completely strip the old paint.

I had planned on re-painting the locomotive anyway, so now is as good a time as any to get it done.

I have always prefered using Easy-Off to strip paint from models. It dosent attack plastic or brass, and seems to cut through just about anything.

Once it is sprayed on it has to sit for about 20 minutes or so to soften up the paint. Then an old, stiff toothbrush is used to scrub off the old paint. I don’t use any water until as much paint as possible has been removed. All the paint that will be coming off will come off at once, sometimes a second application is necessary if the paint has been on the model for a while.

Ya, I know, I should be using gloves, but I couldn’t find them, I need to exfoliate anyway.

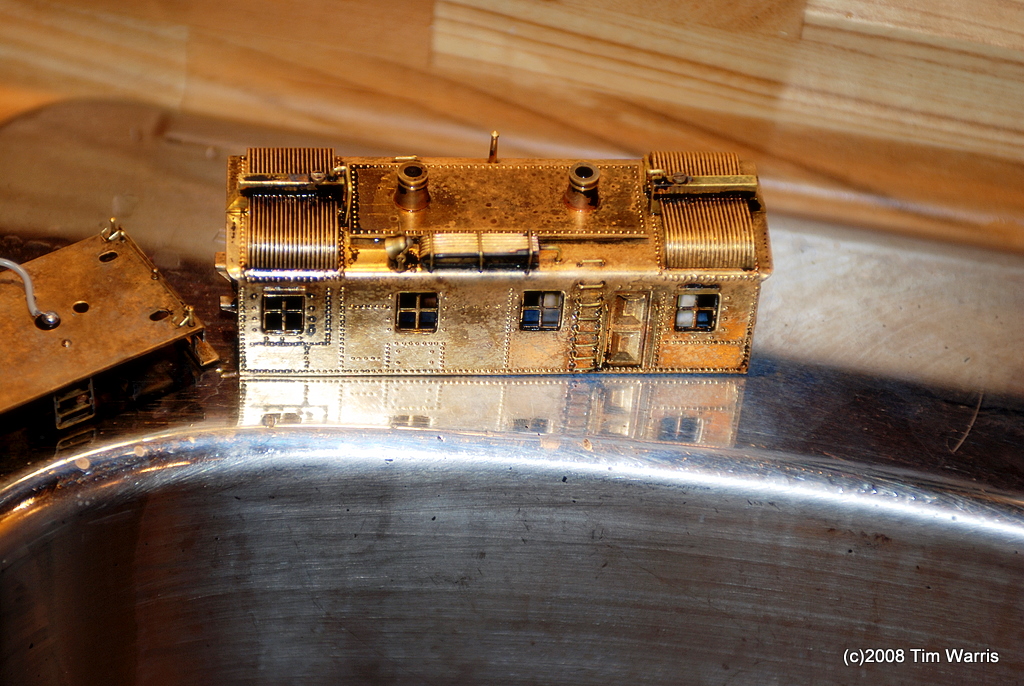

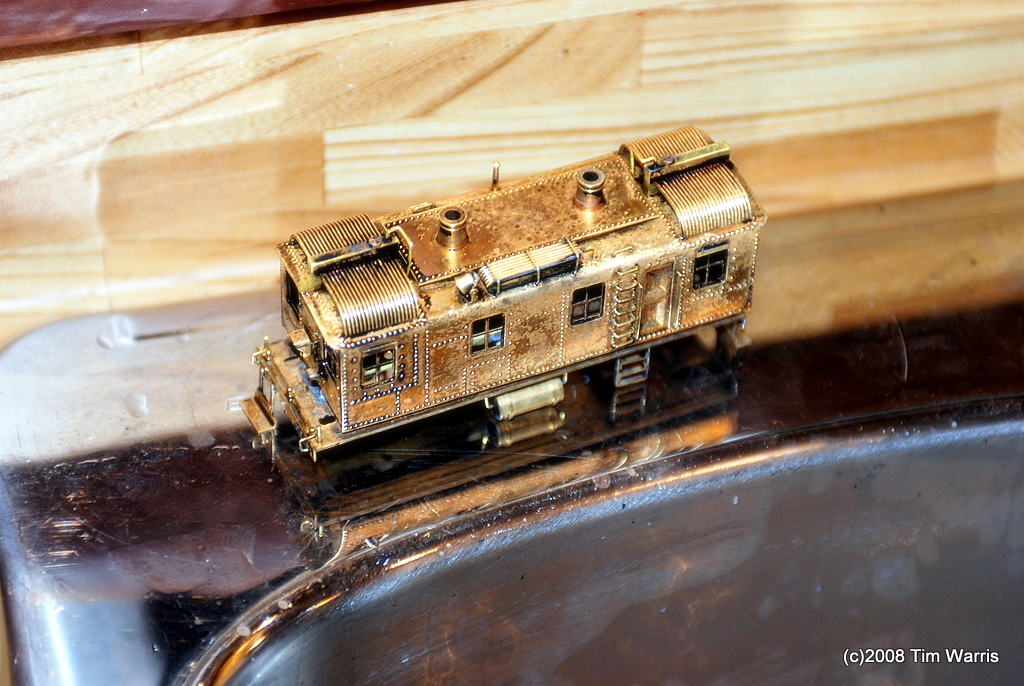

The first pass didn’t remove enough paint on the shell, so I loaded it up again with Easy-Off and let it sit for another 20 minutes. This time it came quite clean.

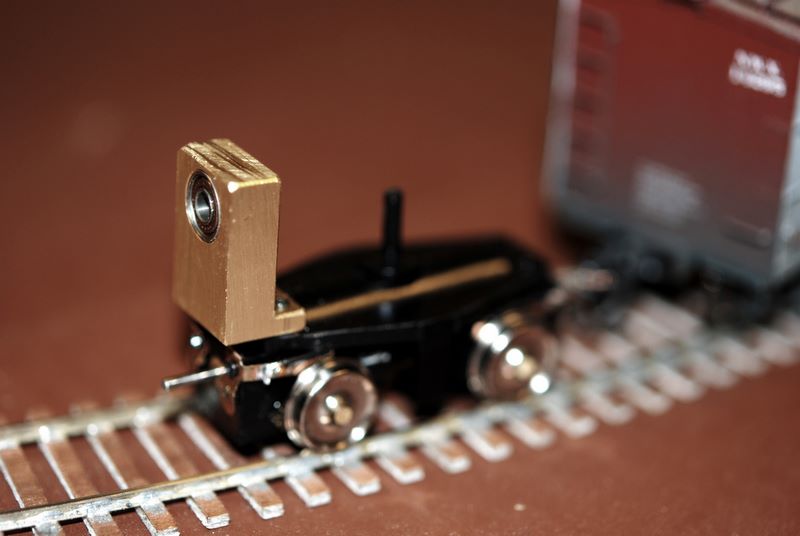

Now that the paint has been removed I can solder on a few parts that had fallen off. The re-motoring is complete and all that is left is to install a decoder and lights. Oh, and paint it.

I really want to add sound, but there are no off the shelf sound decoders even close to this rare engine. What I have found though is MTH’s O scale version of this very engine, and it has sound. I believe they have authentic recordings too.

Here is a video of one I found on YouTube.

My thinking is to buy one and record the sounds into a programmable decoder. I think this will work.

Don’t tell MTH, I hear they are quick with the lawyers…

-T.

I almost forgot, the obligatory dog picture…

On to Next Section

-T.

About the Author:

I'm your host, Tim Warris, a product developer in Port Dover, Ontario. Since March of 2007 I have been documenting the construction of the former CNJ Bronx Terminal in HO scale. For my day job, I design track building tools for Fast Tracks, a small company I own and operate. Fast Tracks makes it fast and easy to hand lay your own trackwork. Stop by our website to learn more!

Posted by: Tim | 11-10-2008 | 10:11 PM

Posted in: CNJ 1000 Boxcab | Latest Posts | Comments (1)