Switch Points

Pivot Points

Once again we are getting some wonderful December weather, so its another good evening for some trackwork. (I’m note sure what the little green eyes are watching.)

After another battle with the upper portion of the house, I am a little tired, so I only worked for a bit on the layout this evening.

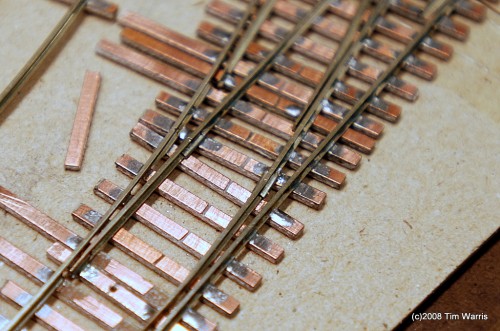

I need to get a reliable method worked out for the numerous switch points on the layout. Most of the points are very short, about an inch or so, so traditional methods won’t work.

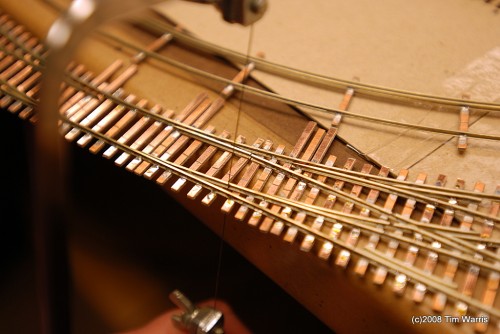

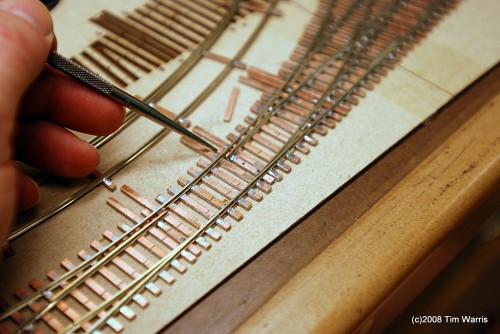

The points were initially soldered in place onto a temporary throwbar, Now, I need to cut them off and pivot them with a hinge. Its the only way to make short points work.

Cutting the points free is easily accomplished with a jewelers saw. The blade can be taken off one end of the saw and fed between the ties and re-attached. The points are sliced free.

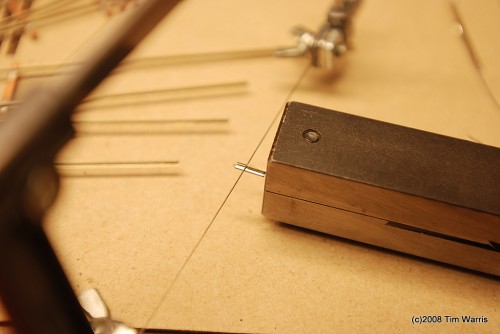

To act as a hinge I cut a code 70 rail joiner to about 2/3 its original length. To hold it while cutting, I slipped it onto a piece of rail held in a PointForm tool.

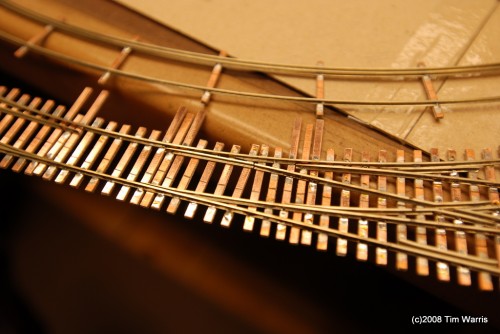

Hinges (rail joiner) soldered in place at the end of the switchpoints. These hold the rail in proper alignment with the stock rail, but still allow the points to pivot enough.

Most of the time this method will work fine with the points soldered to the throwbar, there is enough play in all the parts to allow the points to pivot reliable. With unusually short points this method won’t work.

I can move them well enough, but I am not confident that it will last, there is a bit of tension in the solder joints that I believe is a bit too much and will probably fail.

I have decided to use a method I described a few years back in a Fast Tracks Newsletter (Ok, 5 years ago)

This technique uses a spike that has had the blackening filed off. This spike is inserted into a PC board throwbar that has had the copper foil removed. The spike is then soldered to the switchpoint. This allows the spike to act as a hinge that can freely pivot.

Since the forces being asserted onto the solder joint are not under stress, the joint is unlikely to fail. All the pressure of the switch machine will be on the shank of the spike, not on the solder joint, all the solder is doing is pulling the point back open. Its important to get a solid solder joint, removing the blackening from the spike can not be skipped.

This technique works very well and the points move freely. Its a bit fiddly, but worth the effort.

One down, 27 to go…

-T.

On to Next Section…

About the Author:

I'm your host, Tim Warris, a product developer in Port Dover, Ontario. Since March of 2007 I have been documenting the construction of the former CNJ Bronx Terminal in HO scale. For my day job, I design track building tools for Fast Tracks, a small company I own and operate. Fast Tracks makes it fast and easy to hand lay your own trackwork. Stop by our website to learn more!

Posted by: Tim | 12-06-2008 | 11:12 PM

Posted in: Latest Posts

Tim – how are you handling electrical connectivity to the short hinged points?

With slow speed n-scale operation, it’s a potential dead spot.

I ended up top bonding wire on my hinged points because paint had slipped into most of the hinges during finishing, causing sporadic performance. Not a pretty solution.

Seems like you could solder some pigtails on or near your spikes, but would have to ensure you have a clear slot below so the wire doesn’t hang.

Thoughts?

Hi Chris,

I will solder on a small wire jumper between the stock rail and the switch point. I have done this in the past will good success just using a single strand of copper wire. Its pretty much invisible.

Aaaah! Leaving us all on a cliffhanger. Such gorgeous work. Get on with it willya? Can’t wait to see the spectacular results!

I love the hinges for the points. I was about to ask if you can do it in N Scale (being an N Scale person) till I saw the older post and the N Scale version. That answered that question. Can’t wait to try it out on mine.