Painting Track

No more PC board ties…

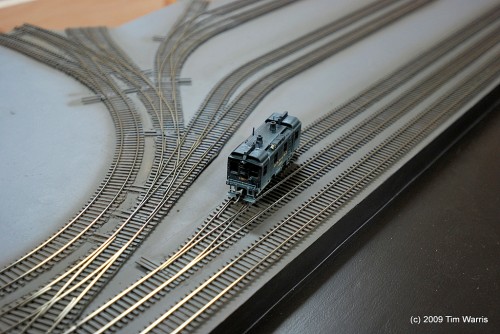

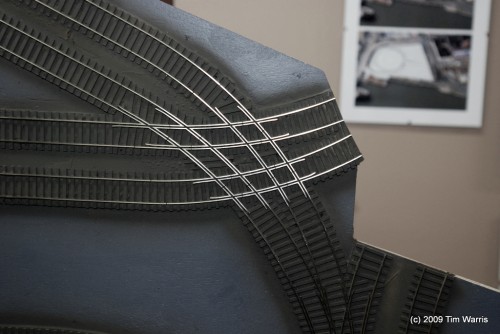

Yesterday I painted all the trackwork on the layout. Well, almost all of it, I decided to leave one three way turnout and a length of track unpainted until after the train show so people can see the construction technique.

If you smelled Floquil paint in the air yesterday, it was from me, sorry about that….

It almost didn’t get done. I started early on it, hoping to finish the painting before noon. I noticed my airbrush needed cleaning, so I took it apart and soaked all the parts in lacquer thinner, which dissolves all the hardened paint deposits. When I reassembled it I had no air. A few minutes playing with it and I realized I should not have soaked the air valve in lacquer thinner as there is an O ring in it that swelled up to twice the size and cut off the air. I hunted up the part number on Badgers site (I have a 155 airbrush) and started phoning around for one. I managed to finally locate on in Dundas, about 35 minutes from here. So I made a trip out to get it, which killed 2 hours.

With that fixed up I started painting, as shown in the video. 2 hours into the job and we had a nasty thunderstorm that knocked out the power for 2 hours. I managed to finish up the painting at 10 pm.

Its all done now, and looks much better. It is only a base coat, I will be doing more to it later prior to ballasting, but for now it is an improvement over the bare copper ties, although that did create a neat effect…

All the track is painted with Floquil’s Railroad Tie Brown, unthinned, straight from the bottle. I used 3 jars for the job. Unfortunately two of the three were from a bad batch and the colour didn’t match the first one very well. It really won’t matter though.

After I paint a section of track, I immediately clean the the paint from the rails using small squares of wood. This makes quick work of cleaning up the rail, and also keeps me from accidentally disturbing the paint on the PC board ties. A few passes is all it takes to get 99% of the paint off the rails. If the paint dries a bit I simply dip the wood block into some lacquer thinner and give it a rub followed with a pass from a dry piece of wood. I cut up a bag of a few hundred of these blocks ahead of time so I have plenty on hand when painting. Once dry, I give everything a cleaning with a bright boy.

This week I also finished off my brass model of CNJ 1000, which there are some shots of in the video.

Getting closer…..

-T.

On to Next Section…

About the Author:

I'm your host, Tim Warris, a product developer in Port Dover, Ontario. Since March of 2007 I have been documenting the construction of the former CNJ Bronx Terminal in HO scale. For my day job, I design track building tools for Fast Tracks, a small company I own and operate. Fast Tracks makes it fast and easy to hand lay your own trackwork. Stop by our website to learn more!

Posted by: Tim | 06-26-2009 | 10:06 AM

Posted in: CNJ 1000 Boxcab | Latest Posts | Track Construction | Video | Weathering

Hi Tim,

Any troubles with the paint gumming up the turnout points or causing the sliding action of the point rails to be sticky? I see you didn’t attempt to mask anything up on the turnouts to keep them clear of paint. Inquiring minds want to know….!

Thanks, Dustin

Hi Dustin,

No issues there. I usually don’t bother masking off the points, I just paint everything and let them dry. Once completely dry they usually just snap free, which they all did.

-T.

Very impressive! I wish you had been around (with Fast Tracks) when I started my layout in 1969. Had to make do with Shinohara, which is good, but isn’t as pretty as Fast Tracks. Actually, I bought one of your turnouts on EBay, and fitted it in, but to take up everything now and replace it would be quite a chore.

CNJ Box Cab – found a Roundhouse plastic kit on EBay, repainted it dark green (Tamiya), and stenciled it with CNJ decals that my local hobby shop still had lying around – gold, with Statue of Liberty logo – looks great. Keep the blogs coming!

Stunning. You must be getting excited at this point knowing that the track work is all but finished. Looking forward to seeing some structures and scenicking(sp?).

Looking good, Tim. Is there an interesting story behind the missing trim around the exterior door, or was it just time to refinish it?

That missing trim has been an irritant for me for the last 3 years. The opposite door is also sans trim.

This room was renovated and used for Fast Tracks for a year when we first moved here, before we built the building out back for Fast Tracks. I simply ran out of time to finish it off before we had to move in.

In the three years since there has just been other priorities and I have simply not had the time to properly finish this room. It will likely be another couple years before I can get to it.

Unless I win the lottery.

Of course that would mean purchasing a lottery ticket.

-T.

Truly amazing. I am glad I found this blog – totally by accident. I am a Certified Financial Planner and closet engineer.

Is there anywhere that I can find photos of your Fast Tracks maufacturing operation? Equipment, finishing, etc. I would love to see how you set things up in the barn.

I don’t do model railroading (yet), but I may just travel to the July show to meet you and see the Terminal.

Thanks,

Cos

Inspirational layout – thanks for putting so much of it online.

Where did you get the paint shaker from?

Thanks,

Peter