Thats alotta engraving.

I completed the first of many sections of paved areas for the terminal today. Kept the laser going for about 4 hours to complete the pieces for this.

Each section I engraved was about 3″x6″ and had to be laminated onto a base, which I framed to simulate the way the pavers were installed in the terminal. Once complete, I gave it a light coat of grey primer.

I am pretty happy with the results. Shows up great in close up shots.

I put quite a bit of effort into the bitmaps used for engraving to ensure there were not noticeable patterns in the brickwork, as there was only a single images duplicated over and over to create the large section.

I was able to do this by carefully manipulating the brightness and contrast of sections of the image, as well as mirroring and flipping it so no two sections were next to each other.

The areas where sections were physically glued together are a bit noticeable, but I am pretty sure I can hide those with some weathering and other details. Unfortunately I won’t be able to do any of that until it is all installed, otherwise I am concerned I will not be able to maintain consistency in the effect.

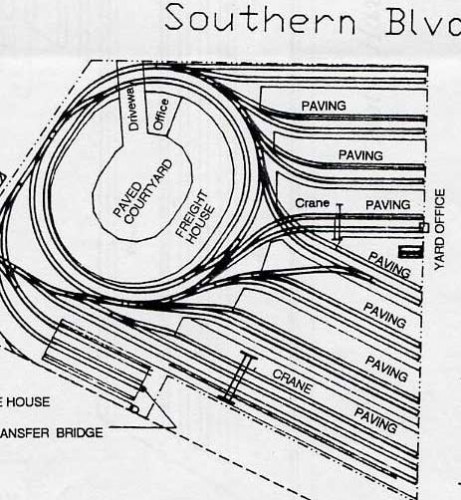

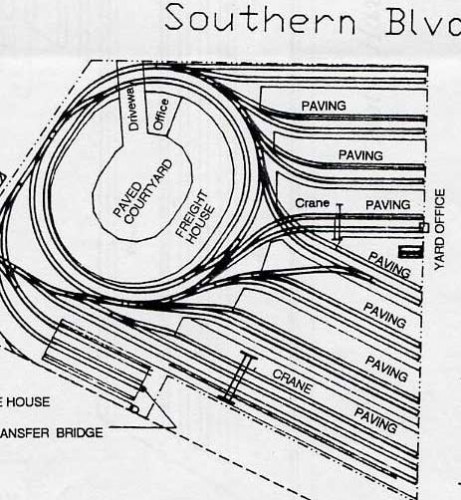

Preparing to pave

I still have not settled on a ballasting technique to use. The grout method has some drawbacks I am not happy with, mainly it looks more like mud than dirt. I will continue experimenting with methods until I find one that will work.

Its just as well, as I can’t apply the ballast until I install a whole lot of cobblestone. A lot of it! Most of the yard was covered in pavers. They extended from the road at the end of the yard tracks, pretty much all the way up to the freight house.

Technique experiments

I have considered a variety of approaches to adding all this cobblestone. Briefly, I thought of carving it into a layer of plaster poured onto the layout. I imagine this would be quite delicate and would likely end up damaged. Plus, I didn’t relish the idea of being slumped over the layout for 11 years carving several square feet of cobblestone. So that idea was shelved.

Enter the laser

About an hour after I unpacked the laser cutter I purchased for Fast Tracks, way back in 2004, I was using it to engrave brick and stone as the sales guy had shown us samples they had made on their laser and I couldn’t wait to give it a try! These things work great at doing this! Initially I drew the brickwork, which works well and allows a lot of flexibility in the detail and shape of the wall, but it is very time consuming.

Yuck. This won’t do. I did give drawing the bricks a shot first for use on the layout as it is nice to be able to make a large single piece of material at once with no noticeable join lines or patterns. The results are less than spectacular, producing stonework that is way to perfect, so this is a no go.

Another method that works great is to simply convert a photograph of a brick wall or stone in to a B&W image, and inverse the tones. Since lasers engrave deeper with darker colours, the B&W image needs to have the light tones made dark, and the dark tones made light, which can be accomplished with most photo editing packages. The results are quite impressive, and I tucked that idea away for a project like this.

We briefly considered adding this as a product to our Fast Tracks line, but decided not to as we make track, and that was to remain our focus. Plus, the laser we have isn’t fast enough to make the product as a reasonable cost. It looks like this is now available commercially, which is great. I just wonder what took so long for someone to market it….

I am quite happy with the results! It will take quite a while to pave the terminal though, the engraving process is a bit slow, plus I will be producing this from small sections that will need to be installed one at a time.

A very nice texture is produced this way, and since it comes from an image of the real thing (well, so of, this is an image of a brick wall I am using for cobblestone) it reproduces almost perfectly.

One little piece complete, a whole lot more to add.

This sample section was engraved onto a sheet of basswood and simply painted with a quick blast of primer I bought at the hardware store. No additional work was done to it, but I suspect I will work it more when I install it for good.

I will make the sheets a bit narrower and frame with timbers as I can see that in one of the images of the terminal I have.

-T.

Testing grout for use as ballast.

After much deliberation I decided the next step in construction would be to start ballasting the trackwork. To be honest, I have been dreading this, as my experience with ballasting is it can make or break a layout. Getting the colours and texture right is critical to creating a good model of the original.

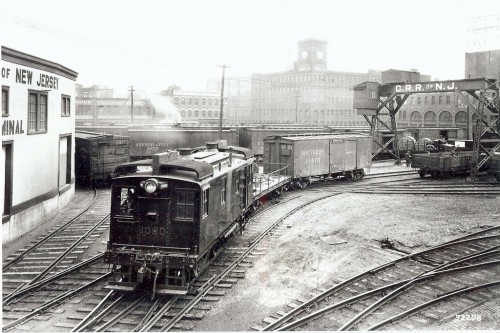

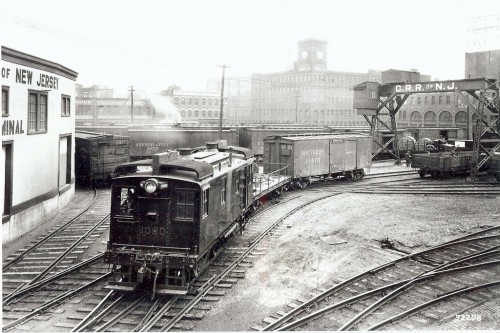

Studying the collection of images I have of the terminal, it is obvious that there was no “ballast” as we know it. It was pretty much all just dirt. To recreate this I don’t think many of the commercial ballasts available would work, so I am trying some alternatives.

Grout is an interesting material to try, as it is much finer that typical ballast, available in lots of colours, and also has the added bonus of being self adhesive…

Not wanting to experiment on the actual layout, I glued a length of flextrack I had on hand to some plywood to test with.

Grout goes on very powdery, almost like talc, but when wetted, turns a bit more grainy. I spread it in place using a brush, then gave it a pre-soak with isopropyl alcohol, followed with water, both applied using spray bottles. An earlier attempt with just water caused the liquid to just sit on top of the grout and not soak in. I was surprised just how much I had to soak it to get it to bond, again, an earlier attempt with a light application of water did not adhere.

Above are a few shots of the results after drying overnight. The bond isn’t as good as I would like, so I will give it another shot with some diluted glue, which should make it pretty permanent.

The texture isn’t bad, but I am not sure if I am 100% happy with the look. Colour might be a bit dark as well.

Here are a couple of images of what I am trying to capture. Click on the images for a larger version….

Comments?