New Product from Fast Tracks to be Released at the NMRA Train Show Next Month!

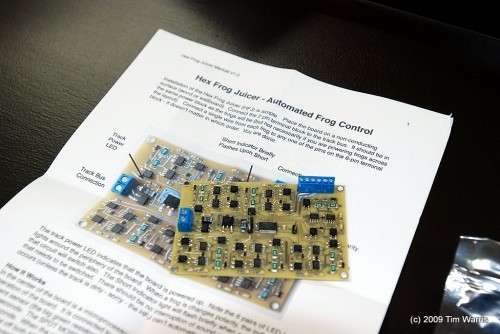

We are planning on releasing a brand new line of money saving products that we think many modelers will find quite useful. We are not ready to reveal any details just yet, but here is a picture of the main product:

To make things interesting, we thought we would have a little contest. Take a guess at what you think this is and post it on our discussion forum at the link below….

Fast Tracks Discussion Forum

The first person to correctly guess what this new product is will win a $100 Gift Certificate from Fast Tracks to be used on our site for anything we sell.

To count, it has to be posted on our forum, otherwise it is difficult to keep track of the guesses. We will reveal the winner after the Train Show, and will not say if or when a correct guess has been entered until the end of the contest.

So, what do you think it is?

-T.

note: if I have already shown you the product, please don’t cast a guess. I’ll remember. Bob, Clark, Pierre, The CASO Free-mo club and anyone at Credit Valley, this means you. And anyone else who has seen it. Play fair.

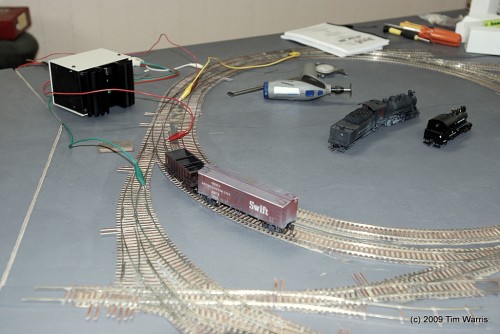

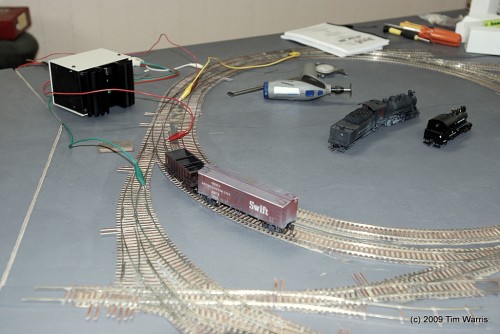

Tortoises installed, feeders being added.

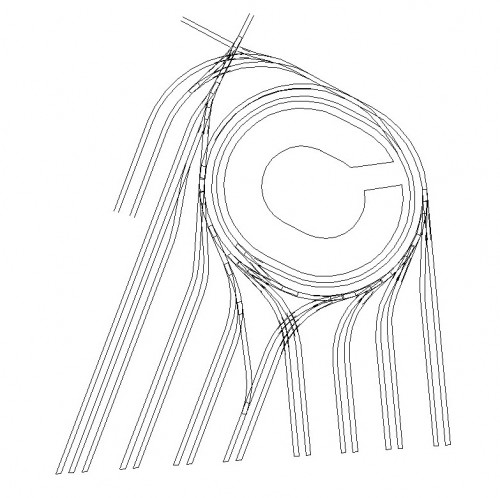

On the left is one half of the layout with all the switch machines installed. Its amazing how much of a mess gets made installing a few switch machines. The right side of the layout is also complete. 28 in total. There are two more to add, one under a turnout I still have to build, and one on the float bridge I still have to build.

I think I have set a SMDL (switch machine density level) record, 17 machines in about 3 square feet.

Nothing important about this picture, just showing a mess.

I cobbled together some feeders and took an engine for a short spin on what sections of track I would get operable. It was very thrilling. Neither of these engines belong on the terminal, they are all I have on hand at the moment.

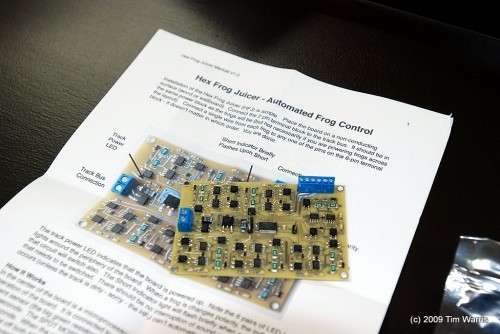

This nifty little unit is going to same me a ton of time and headaches. What it does is take over the switching of the frog polarity on complex track. A single feeder is run to an isolated frog and the board is connected to the track feeders. When a train comes in contact with the frog, it will switch the frog polarity to the correct direction, instantly. Using this really helps with crossings, which can be difficult to control when using switch machines, especially the kind of crossings I am using. With this, I simply run a feeder to the frogs in the crossing. One unit will operate 6 frogs.

Its called a Hex Frog Juicer, by Tam Valley Railway.

When I have it operating I will post a video of it. Would be great for anyone using ground throws.

I made a road trip to lay in some supplies. Starting with some wire for feeders. Shown here is some 22GA solid wire for the frogs and track feeders. Also some 2 conductor 22GA wire for switch machine power.

I also paid a visit to Bob Scott at Credit Valley Railway and picked up a DT400IR throttle and receiver. Grabbed a power supply for the DCC system while I was there as well.

The initial plan for the layout was to use stationary decoders to control the switch machines. After a bit of thought I decided to go with simple toggle switches and control panels instead to keep it simple. After more thought, I went back to the original idea of using stationary decoders. I really didn’t design the layout for control panels, and adding them in now would be a hack. After playing with the DT400 a bit it seems that is will work well enough to operate the layout using it with stationary decoders.

I have been asked why I didn’t just use simple ground throws. The answer is easy, they are damn ugly. Also, reaching into the layout to operate them is hazardous. Although I am considering Sergent Couplers for the cars, so I am contradicting myself a bit. If there was a good looking, durable ground throw with contacts for frog switching, I would have considered it, and since I don’t have time to develop one myself, I will stick to the tried and true Tortoises with DS-64 stationary decoders.

BTW, does anyone know how many routes are possible if using multiple DS-64’s for turnout control? I have asked everyone, looked online and even called Digitrax. No one seems to know, even the tech support guy at Digitrax! Am I the only person in the model railroading universe that is doing this?

Above are the 8 DS-64’s I need for the layout. Actually, I only have 5 at the moment, Bob has three more on order for me. 3 of the DS-64’s in the picture above were added in using Photoshop. Bob, if you’re reading this, I still need three more. Don’t let the picture fool you.

Today, I added all the feeders from the switch machines to the frogs. This evening, I installed the main bus line, using 12GA wire (in black and white near the bottom of the layout section. Using suitcase connectors I have started adding the feeders to the rails and also to the switch machines. One half is almost complete, will try to get the other side done tomorrow, then start with the DS-64 installations. After that, a test run!

-T.

On to Next Section…

Looking for suggestions…

I realize asking any “which system is best” DCC question is like asking which religion should I join, so hopefully this won’t break down into a non productive argument.

I am looking for advice from modelers who are familiar with a variety of systems and might have some advice on which system would work best for the type of layout I am building and will be operating.

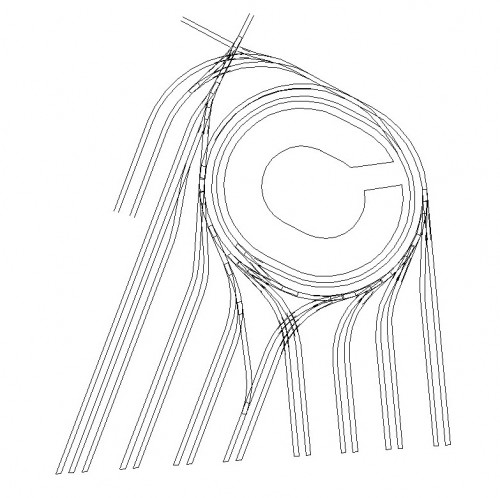

Over the next several weeks I will be completing the trackwork on my CNJ Bronx Terminal layout and am at the point where I need to make some decisions on control.

Here is a list of what I require, which is a bit unique with this type of layout.

- Only one locomotive will ever operate on this layout at one time. Ever.

- DCC sound equipped engines will be operated (again, only one at a time)

- 30 turnouts powered with Tortoise machines

- approximately 30 individual and complex routes, some requiring the operation of up to 14 machines

The layout is a single operator layout that will be primarily used at shows. I intend on operating the layout in a prototype manner with some sort of switch list or card system. Typical operation will consist of selecting one of the 30 routes from a hand held throttle and switching that track. All equipment will use Sergent couplers, so manual operation of the couplers will be necessary, therefore reaching into the layout isn’t an issue. All tracks on the layout are accessible from one of 3 sides. I anticipate typical operation will involve walking the perimeter of the layout often to reach cars. There will be no stationary control panel on the layout, all operation is to be done using the hand held throttle.

The DCC system I will require MUST have quick and easy route selection ability. I would rather not have to spend time fiddling with more buttons than necessary to select a route, this should be able to be done quickly and intuitively.

Stationary decoders will be used to operate the 30 Tortoise machines on the layout. I am looking for a system that offers easy set up and configuration of the routes. The stationary decoders should be able to route power to the frogs independently of the switch machines if possible. If I can avoid using the contacts on the Tortoises for this it would make setting up the routes in this complex trackwork much more reliable.

An added bonus would be the ability to use a computer to pre-program the routes and the hand held unit to operate the layout (I don’t want to have a computer attached to the layout for operation).

All this said, any suggestions which system/stationary decoders would offer the most efficient operation and ease of use?

Currently I have an older Digitrax system, but have no issues purchasing any other system for this layout, the priority is reliable operation. So far, my experience with Digitrax has not been simple. Any system that shows me hexadecimal numbers might end up near the bottom of the list….

Contact me via email (tim@warris.com) or in the comments box below.

-T.

Update – May 11

I spent the weekend analyzing the layout and what I will be using it for.

I received a lot of feedback both here and at Model Railroad Hobbyist about this and have come to the conclusion that the best approach might be to use simple toggle switches on two control panels to operate the turnouts instead of using a more technological routing method.

Setting up the 30 or so routes for this complex yard will likely lead to a cumbersome method of operating. I would have to memorize the routes, and in the end I think I would lose some flexibility of operation if limited to pre-set routes. Having individual control of each turnout would add the flexibility required for this type of layout.

My last layout, The Port Kelsey Ry, I used route selection on the control panels, with a diode matrix to set the routes. This worked very well for the type of yards I was operating, and made operation much more intuitive. Although the amount of work required to set this up was staggering!

This is 1/4 of the electrical panel required to make the main yard work (it had a bit of complex track on it too). The far left is the diode matrix portion.

I will make up a couple neat looking control panels, and install them into the rusty fascia of the layout, something similar to this…

I played with lots of different possibilities for turnout control, from a laser pointer activated turnout, to a push button switch stand to a magnetically activated turnout, but decided to go with toggles as I really don’t want the layout to be about how the turnouts are operated. Will keep those projects for something else….

For a DCC system, I will likely stick with my Digitrax, and get a DT-400R throttle. For a sound equipped locomotive, this should work well.

-Tim