Trackwork Tedium

but its getting done!

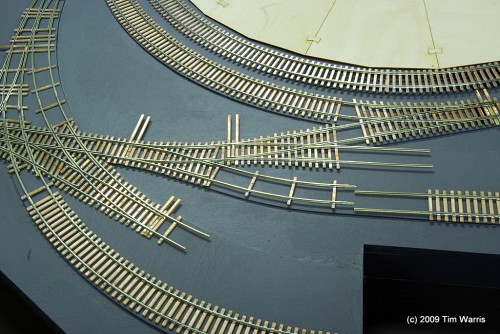

For the last couple of evenings I have returned to finishing off the trackwork. I admit, I have been procrastinating with this job because it is a bit on the tedious side. One of these days I will have to count just how many PC board ties I have soldered in place on this layout, several thousand I suspect.

The results are worth it though, the finished track sections are rock solid and will never move, very important with trackwork such as this.

The hinging technique for the points also seems to be working well. I can get two turnouts done in an evening.

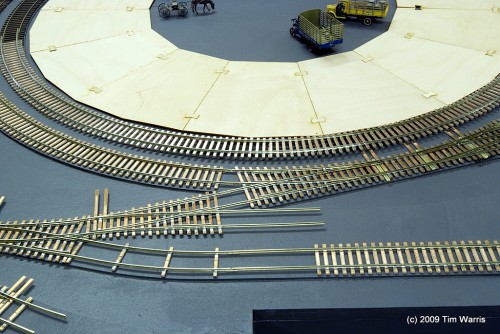

Most of the missing PC board ties have been added in to these sections. I also finished off the curved track for the inner circle.

As I add in the missing ties, I also finish off the switch points, so the trackwork is fully completed and ready for the next phase of construction, which is cutting the rail gaps. I don’t want to cut the gaps until I am ready to install the track in place as it will become weak. I would love to get this done, so people will stop asking how I am going to do it!

A bit of progress. I think there are now 8 turnouts completed. The next section of trackwork consists of 8 more turnout points, so that should take a few more evenings.

I should have used Photoshop to remove that double chin in the first picture.

-T.

On to Next Section….

About the Author:

I'm your host, Tim Warris, a product developer in Port Dover, Ontario. Since March of 2007 I have been documenting the construction of the former CNJ Bronx Terminal in HO scale. For my day job, I design track building tools for Fast Tracks, a small company I own and operate. Fast Tracks makes it fast and easy to hand lay your own trackwork. Stop by our website to learn more!

Posted by: Tim | 02-25-2009 | 11:02 PM

Posted in: Latest Posts | Track Construction

I’ve been following the Terminal project since the beginning I think. Fantastic work. In a way I will be sad when you finish it 🙂 I will have to try to get out east and see it in person some day.

Your blog is marked in my feed reader and I always look forward to your posts.

I used to use Photoshop but decided it was easier to grow a beard.

You are insane! So awesome! 😀

Tim

Just one question- Is the white area the footprint of the building to go in the center and if so, the one set of head ties is under the building from the shot posted today. Good to know that even the pro get confused like the rest of us. LOL

Jim

Tim::

Outstanding work!

Given the complexity of the trackwork, I would expect that even with

DCC the number of gaps that need to be cut will significant. Have you considered battery power and through-the-air radio control for the layout?

.vp

Hi,

I have often considered using a RC/battery system, but one problem remains, no one makes one!

Which is very hard to believe, a huge opportunity is waiting someone who has the capital to develop such a system.

-T.

Hi! I was surfing and found your blog post… nice! I love your blog. 🙂 Cheers! Sandra. R.