Paint jar storage.

Drawer insert.

My last bench had space for about 30 jars of paint placed on a small shelf at the back of the bench. I quickly overwhelmed this space with about 100 jars of Floquil paint. I prefer Floquil paint and snap them up whenever I find them at a good deal so this has lead to quite a pile of jars. The paint jars took up quite a bit of space on the bench so I decided this time to make a drawer dedicated for the paints. Not wanting them sliding all over the place when the drawer is opened and closed I make a divider to hold the jars steady.

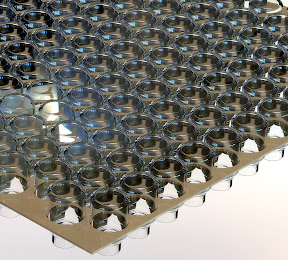

I cut the divider from two layers of 2mm plywood (the same wood we use for HO scale QuickSticks). It sits on 1/2″ rails 2″ high and has 1.5″ diameter holes patterned as tightly as possible to fit a maximum amount of jars.

I drew it all up with our CAD system to help layout the patterns and did a quick rendering for no reason at all. The image with all the inverted clear jars is completely computer generated.

I keep the paint jars stored upside down for a couple of reasons, mainly so I can quickly identify the paint colour. One advantage of keeping them inverted is that they never dry out this way, I have some jars that are over 10 years old and are still and good as new.

-Tim

About the Author:

I'm your host, Tim Warris, a product developer in Port Dover, Ontario. Since March of 2007 I have been documenting the construction of the former CNJ Bronx Terminal in HO scale. For my day job, I design track building tools for Fast Tracks, a small company I own and operate. Fast Tracks makes it fast and easy to hand lay your own trackwork. Stop by our website to learn more!

Posted by: Tim | 12-16-2007 | 10:12 AM

Posted in: Latest Posts | Work Bench | Comments Off on Paint jar storage.