Getting ready to add some ballast – experiments.

Testing grout for use as ballast.

After much deliberation I decided the next step in construction would be to start ballasting the trackwork. To be honest, I have been dreading this, as my experience with ballasting is it can make or break a layout. Getting the colours and texture right is critical to creating a good model of the original.

Studying the collection of images I have of the terminal, it is obvious that there was no “ballast” as we know it. It was pretty much all just dirt. To recreate this I don’t think many of the commercial ballasts available would work, so I am trying some alternatives.

Grout is an interesting material to try, as it is much finer that typical ballast, available in lots of colours, and also has the added bonus of being self adhesive…

Not wanting to experiment on the actual layout, I glued a length of flextrack I had on hand to some plywood to test with.

Grout goes on very powdery, almost like talc, but when wetted, turns a bit more grainy. I spread it in place using a brush, then gave it a pre-soak with isopropyl alcohol, followed with water, both applied using spray bottles. An earlier attempt with just water caused the liquid to just sit on top of the grout and not soak in. I was surprised just how much I had to soak it to get it to bond, again, an earlier attempt with a light application of water did not adhere.

Above are a few shots of the results after drying overnight. The bond isn’t as good as I would like, so I will give it another shot with some diluted glue, which should make it pretty permanent.

The texture isn’t bad, but I am not sure if I am 100% happy with the look. Colour might be a bit dark as well.

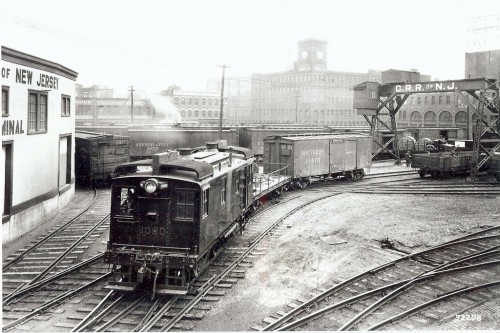

Here are a couple of images of what I am trying to capture. Click on the images for a larger version….

Comments?

About the Author:

I'm your host, Tim Warris, a product developer in Port Dover, Ontario. Since March of 2007 I have been documenting the construction of the former CNJ Bronx Terminal in HO scale. For my day job, I design track building tools for Fast Tracks, a small company I own and operate. Fast Tracks makes it fast and easy to hand lay your own trackwork. Stop by our website to learn more!

Posted by: Tim | 03-20-2012 | 02:03 PM

Posted in: Ballast | Latest Posts | Track Construction | Weathering | Comments (6)