The Doors

Hang time

The Bronx project has stalled a bit the last few days. I am in the middle of a major Honey-do. I suspect a few more weeks and I should be back at the layout in earnest….

This weekend I am working on installing a few new doors in what will eventually be a bedroom.

The door into the room from the hallway had to be completely replaced, including the door jam. The old door and jam had been hacked up pretty good, I think the last attempt at a reno involved axes. Instead of trying to restore the old door I decided to replace it. Actually, all the doors on the second floor will be replaced with new ones, but I think I will only have to replace this one door jam.

Of all the jobs in house renovating, installing a door is by far the more difficult. Nothing is more evident that a poorly hung door. To date, I don’t think I have done one to my satisfaction. Perfect door hangage requires the the following features:

- Level

- Plumb

- Square

- 1/8″ to 3/16″ space on the hinge side

- Parallelism to 1/32″

- Precise installation of hinges (damn near impossible)

- No play between the door and the jam

- No binding between door and the jam

- Door will not pivot on its own.

- Latch functions correctly

- I’m sure there is something else

These doors are all pretty good, but next time they will be a bit better…

The outside of the room. I installed the new jam wiithout removing all of the old trimwork. Removing it would start a chain reaction of projects that would lead to tearing down the house. This ment working within the accuracy of the original trimwork that wasen’t too bad, but not perect. I will blame any error in my install on that.

I’d give this install a 9 out of 10. I’m not happy with the location of the hinges. The striker plate could be better too.

The second door in the room leads into the laundry room. This one, I’d give an 8 out of 10. Again, not happy with the striker plate. Everything else is pretty good. 100% better than the useless bi-fold door disaster that was there before.

I managed to install two doors today, which is a record for me. If installing a simple pre-hung door, getting several of them done in a single day would be easy. These are doors that need the hinges and handles installed, and also complete door jams built. That slows down production quite a bit.

They are done. Tomorrow I will start the electrical and be that much closer to returning to the layout project.

That is all I have to say about installing doors.

-T.

About the Author:

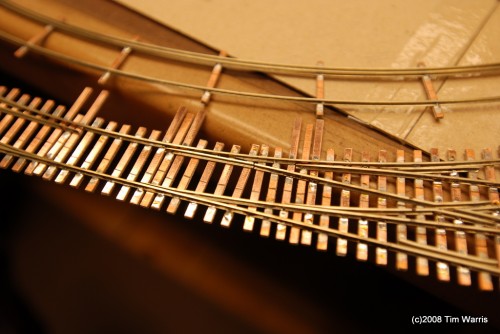

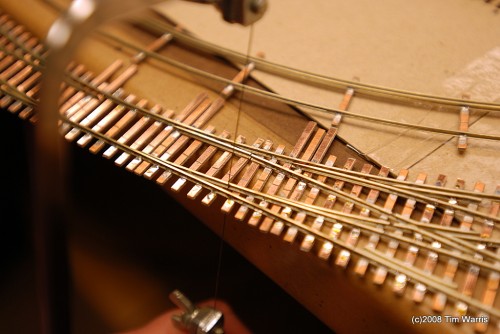

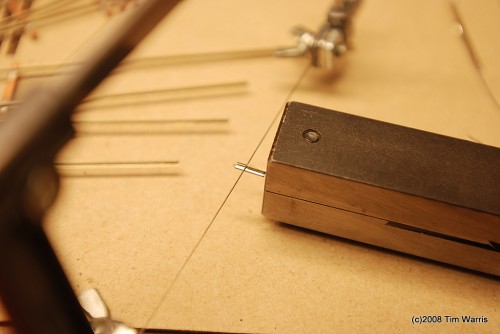

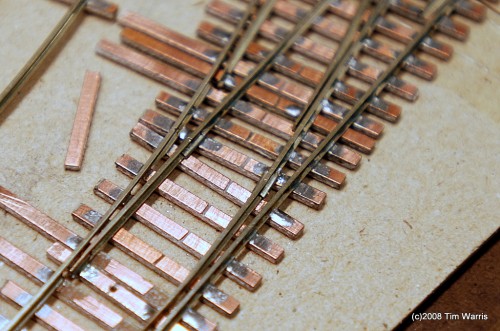

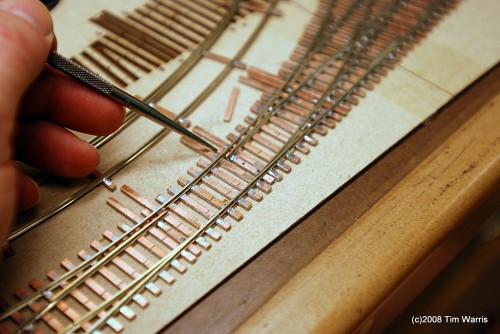

I'm your host, Tim Warris, a product developer in Port Dover, Ontario. Since March of 2007 I have been documenting the construction of the former CNJ Bronx Terminal in HO scale. For my day job, I design track building tools for Fast Tracks, a small company I own and operate. Fast Tracks makes it fast and easy to hand lay your own trackwork. Stop by our website to learn more!

Posted by: Tim | 12-14-2008 | 12:12 AM

Posted in: 2007 NMRA Train Show - Detroit | Latest Posts | Our Old House | Comments (2)