Gaps

Gapping complex trackwork.

The number one thing I get asked about when someone sees this trackwork is “how will you wire this?”. Seeing all those frogs it looks very complex but once you understand the basics of where to isolate sections of track you develop an eye for where to cut the gaps.

I design a lot of complex trackwork and part of the design is determining where modelers will need to cut gaps to have the trackwork operate properly. DC or DCC, the gapping is the same when building ultra-reliable track. To have trackwork (turnouts and crossings) work without shorts or equipment stalling it is necessary to “cut the frogs out”, that is to completely isolate the frog from the rest of the turnout and feed power to the frog independently from the turnout. Power is supplied to the frog from either a switch machines contacts or from a ground throw that has contacts on it.

The link will show a animated rendering showing how this works….

Rendering illustrating switching power to a frog.

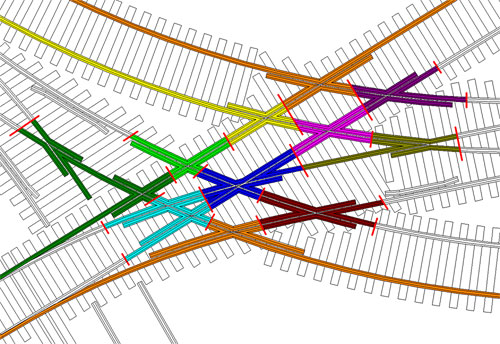

The “polarity” of the frog is set to match either the “north” or “south” rail depending on which way the turnout is set. The same is true for multi frog trackwork. Each location where two rails cross each other (frogs) will need to be isolated from the rest of the track and powered independently based on the route selected.

Image Copyright (c) 2007 Tim Warris

What I have illustrated here is all the different frogs in the first section of trackwork built. The gaps cut through the rails are shown in red. After studying the drawing for a while and thinking how a train would run through the trackwork I determined where each frog would have to be cut using a jewelers saw.

Power will be fed to each frog from the contacts of switch machines relative to the route selected. Additional contacts will be needed and will be supplied from relays connected to the switch machine contacts.

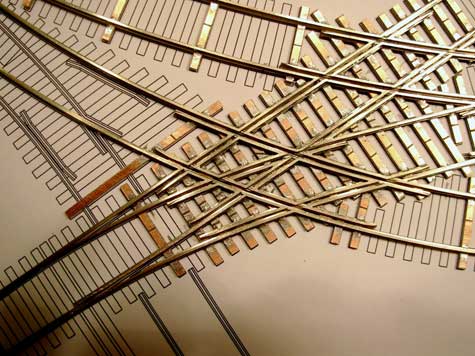

It isn’t as difficult as it appears, but when complete there will be lots of wires feeding all the different frogs, which does make it appear complex, but in reality it is the same circuit repeated several times. You end up with stuff like this…

But it runs 100% reliably!

-Tim

About the Author:

I'm your host, Tim Warris, a product developer in Port Dover, Ontario. Since March of 2007 I have been documenting the construction of the former CNJ Bronx Terminal in HO scale. For my day job, I design track building tools for Fast Tracks, a small company I own and operate. Fast Tracks makes it fast and easy to hand lay your own trackwork. Stop by our website to learn more!

Posted by: Tim | 04-04-2007 | 10:04 PM

Posted in: Latest Posts