A few hundred thousand cobblestones.

Preparing to pave

I still have not settled on a ballasting technique to use. The grout method has some drawbacks I am not happy with, mainly it looks more like mud than dirt. I will continue experimenting with methods until I find one that will work.

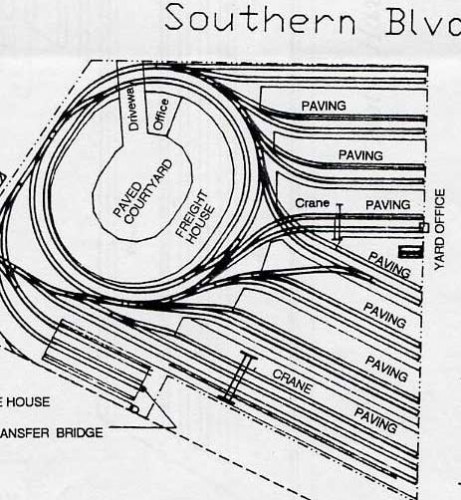

Its just as well, as I can’t apply the ballast until I install a whole lot of cobblestone. A lot of it! Most of the yard was covered in pavers. They extended from the road at the end of the yard tracks, pretty much all the way up to the freight house.

Technique experiments

I have considered a variety of approaches to adding all this cobblestone. Briefly, I thought of carving it into a layer of plaster poured onto the layout. I imagine this would be quite delicate and would likely end up damaged. Plus, I didn’t relish the idea of being slumped over the layout for 11 years carving several square feet of cobblestone. So that idea was shelved.

Enter the laser

About an hour after I unpacked the laser cutter I purchased for Fast Tracks, way back in 2004, I was using it to engrave brick and stone as the sales guy had shown us samples they had made on their laser and I couldn’t wait to give it a try! These things work great at doing this! Initially I drew the brickwork, which works well and allows a lot of flexibility in the detail and shape of the wall, but it is very time consuming.

Yuck. This won’t do. I did give drawing the bricks a shot first for use on the layout as it is nice to be able to make a large single piece of material at once with no noticeable join lines or patterns. The results are less than spectacular, producing stonework that is way to perfect, so this is a no go.

Another method that works great is to simply convert a photograph of a brick wall or stone in to a B&W image, and inverse the tones. Since lasers engrave deeper with darker colours, the B&W image needs to have the light tones made dark, and the dark tones made light, which can be accomplished with most photo editing packages. The results are quite impressive, and I tucked that idea away for a project like this.

We briefly considered adding this as a product to our Fast Tracks line, but decided not to as we make track, and that was to remain our focus. Plus, the laser we have isn’t fast enough to make the product as a reasonable cost. It looks like this is now available commercially, which is great. I just wonder what took so long for someone to market it….

I am quite happy with the results! It will take quite a while to pave the terminal though, the engraving process is a bit slow, plus I will be producing this from small sections that will need to be installed one at a time.

A very nice texture is produced this way, and since it comes from an image of the real thing (well, so of, this is an image of a brick wall I am using for cobblestone) it reproduces almost perfectly.

One little piece complete, a whole lot more to add.

This sample section was engraved onto a sheet of basswood and simply painted with a quick blast of primer I bought at the hardware store. No additional work was done to it, but I suspect I will work it more when I install it for good.

I will make the sheets a bit narrower and frame with timbers as I can see that in one of the images of the terminal I have.

-T.

About the Author:

I'm your host, Tim Warris, a product developer in Port Dover, Ontario. Since March of 2007 I have been documenting the construction of the former CNJ Bronx Terminal in HO scale. For my day job, I design track building tools for Fast Tracks, a small company I own and operate. Fast Tracks makes it fast and easy to hand lay your own trackwork. Stop by our website to learn more!

Posted by: Tim | 04-07-2012 | 06:04 PM

Posted in: Latest Posts

Those pavers look really good

Tim,

Came across your site on a hunt for billboard reefers of all things. I’ve now spent a good hour reading and watching your trackwork diary and the progress you’ve made. All I can say is wow and where the heck was this website when I was learning the art of rail weaving for my layout?

Seriously , You’ve solved several of my problems and using track spikes for throw pivots was a stroke of genius. Thanks for making the painful decisions and dealing with the aftermath on your project, I think it will make mine go much easier now.

P.S. My chief engineer drinks as well , he also leaves his bottles on the layout.

Jeff Rich

Mt. Juliet,Tn.

Tim,

The brick paving looks spectacular, I hope it will become one of your retail products. It’s worth sharing.

Super job.

Ralph (CN6401)