Time to Decide on a DCC System – UPDATED

Looking for suggestions…

I realize asking any “which system is best” DCC question is like asking which religion should I join, so hopefully this won’t break down into a non productive argument.

I am looking for advice from modelers who are familiar with a variety of systems and might have some advice on which system would work best for the type of layout I am building and will be operating.

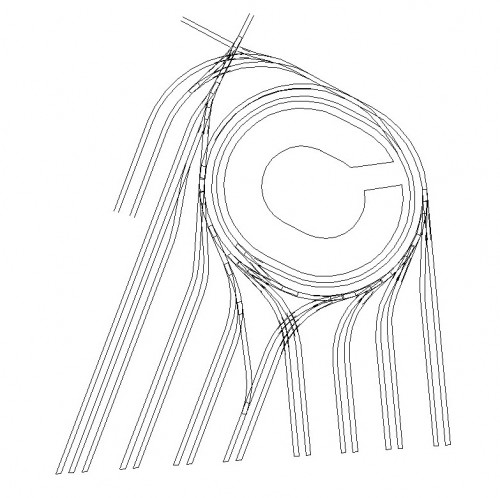

Over the next several weeks I will be completing the trackwork on my CNJ Bronx Terminal layout and am at the point where I need to make some decisions on control.

Here is a list of what I require, which is a bit unique with this type of layout.

- Only one locomotive will ever operate on this layout at one time. Ever.

- DCC sound equipped engines will be operated (again, only one at a time)

- 30 turnouts powered with Tortoise machines

- approximately 30 individual and complex routes, some requiring the operation of up to 14 machines

The layout is a single operator layout that will be primarily used at shows. I intend on operating the layout in a prototype manner with some sort of switch list or card system. Typical operation will consist of selecting one of the 30 routes from a hand held throttle and switching that track. All equipment will use Sergent couplers, so manual operation of the couplers will be necessary, therefore reaching into the layout isn’t an issue. All tracks on the layout are accessible from one of 3 sides. I anticipate typical operation will involve walking the perimeter of the layout often to reach cars. There will be no stationary control panel on the layout, all operation is to be done using the hand held throttle.

The DCC system I will require MUST have quick and easy route selection ability. I would rather not have to spend time fiddling with more buttons than necessary to select a route, this should be able to be done quickly and intuitively.

Stationary decoders will be used to operate the 30 Tortoise machines on the layout. I am looking for a system that offers easy set up and configuration of the routes. The stationary decoders should be able to route power to the frogs independently of the switch machines if possible. If I can avoid using the contacts on the Tortoises for this it would make setting up the routes in this complex trackwork much more reliable.

An added bonus would be the ability to use a computer to pre-program the routes and the hand held unit to operate the layout (I don’t want to have a computer attached to the layout for operation).

All this said, any suggestions which system/stationary decoders would offer the most efficient operation and ease of use?

Currently I have an older Digitrax system, but have no issues purchasing any other system for this layout, the priority is reliable operation. So far, my experience with Digitrax has not been simple. Any system that shows me hexadecimal numbers might end up near the bottom of the list….

Contact me via email (tim@warris.com) or in the comments box below.

-T.

Update – May 11

I spent the weekend analyzing the layout and what I will be using it for.

I received a lot of feedback both here and at Model Railroad Hobbyist about this and have come to the conclusion that the best approach might be to use simple toggle switches on two control panels to operate the turnouts instead of using a more technological routing method.

Setting up the 30 or so routes for this complex yard will likely lead to a cumbersome method of operating. I would have to memorize the routes, and in the end I think I would lose some flexibility of operation if limited to pre-set routes. Having individual control of each turnout would add the flexibility required for this type of layout.

My last layout, The Port Kelsey Ry, I used route selection on the control panels, with a diode matrix to set the routes. This worked very well for the type of yards I was operating, and made operation much more intuitive. Although the amount of work required to set this up was staggering!

This is 1/4 of the electrical panel required to make the main yard work (it had a bit of complex track on it too). The far left is the diode matrix portion.

I will make up a couple neat looking control panels, and install them into the rusty fascia of the layout, something similar to this…

I played with lots of different possibilities for turnout control, from a laser pointer activated turnout, to a push button switch stand to a magnetically activated turnout, but decided to go with toggles as I really don’t want the layout to be about how the turnouts are operated. Will keep those projects for something else….

For a DCC system, I will likely stick with my Digitrax, and get a DT-400R throttle. For a sound equipped locomotive, this should work well.

-Tim

About the Author:

I'm your host, Tim Warris, a product developer in Port Dover, Ontario. Since March of 2007 I have been documenting the construction of the former CNJ Bronx Terminal in HO scale. For my day job, I design track building tools for Fast Tracks, a small company I own and operate. Fast Tracks makes it fast and easy to hand lay your own trackwork. Stop by our website to learn more!

Posted by: Tim | 05-09-2009 | 01:05 PM

Posted in: Latest Posts | Track Construction | Comments (7)